2024.10.16

Installation steps and technical requirements of four-column four-wheel positioning lift

Page view:147

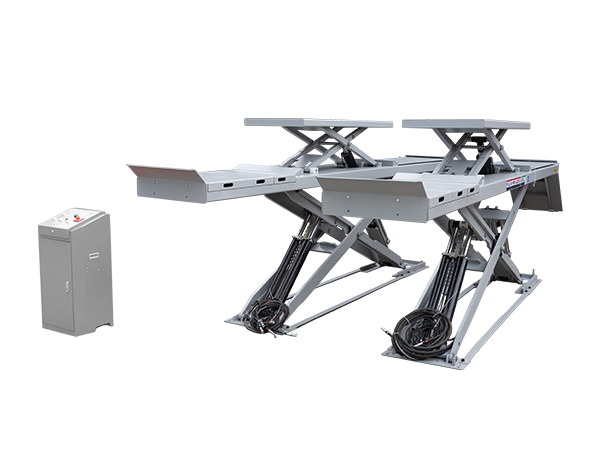

After purchasing four-column four-wheel positioning car lift, auto repair friends will worry about how to install it? How to install to achieve the best use state? We all know that the installation and commissioning of mechanical equipment is very important, which is related to the long life of mechanical equipment, all-round safety, convenience, low maintenance cost of a series of long-term experience and practical economic benefits. Now let me introduce the installation program steps and debugging methods of the 4-ton lifting weight four-column positioning elevator.

Four column positioning lift installation foundation and power requirements:

The ground and concrete must comply with the regulations, otherwise it will lead to the lifting machine or vehicle falling off accidents.

one One-time concrete structure, thickness of not less than 150mm and no reinforcement, must be completely dry before installation;

2. The concrete strength must be greater than 3000PSI(approximately 210kg/cm²); Can be used to test the impact drill, drilled powder showing fine powder square is qualified, such as drilled cement is granular, strength unqualified need to dig the foundation!

3. The installation ground must be smooth and level without cracks.

4. Power capacity must be greater than 2.2kw, wire diameter greater than 2.5mm², and must be well grounded.

Four-column positioning lift installation step 1: (1) After determining the site is OK, first remove the fixed frame. Put all the accessories aside, then check all the accessories against the list.

Four-column positioning elevator installation step 2: (1) Use an ink fountain to flick the line on the ground, determine the installation position, use an ink fountain to pop out the installation position according to the installation size of the four-column elevator, and then place the column according to the installation size (note: appropriate space must be reserved before and after the installation position) : Play the two lines A and B and the equivalent lines C and D, remember that line A and the opposite side line consistent length of 4700mm, line B and the opposite side line consistent length of 3206mm, rectangular diagonal line C length of 5689mm, note: the deviation can not be too large! Otherwise, the efficiency and quality of the installation will be affected.

Four-column positioning lift installation step three: (1) Install the beam, (note that the beam opening direction is inside and the side with the safety mechanism rotation component should be the same side as the column on which the hydraulic station is installed). Note: 1, the column and beam of the installation hydraulic station should be on the same side of the beam opening direction to the inside, and the side with the safety mechanism rotating component should be on the same side as the column of the installation hydraulic station. 2, the column with the beam opening direction to the inside should be on the same side.

Step 4 of installing a four-column positioning lift: (1) Prepare anchor bolts. Drill the holes for installing anchor bolts using a hammer drill, install anchor bolts, and hammer the anchor bolts into the ground. Do not tighten the anchor bolts.

* Note: Anchor screws are driven at least 90mm into the ground.

Four column positioning lift installation step five: (1) Install the safety support: first remove a nut of the safety support, and adjust the four safety support another nut to the same position, and then install the safety support. The safety support is inserted between the limit pins from the top down, and the safety support passes between the limit pins of the beam. (2) The height of the four safety support screws should be the same, and the safety support should pass through the top hole and lock the two nuts to each other. (3) Raise the beam to the same height, and stuck on the safety support, the beam safety mechanism should be stuck to the safety support of the same level of insurance, the height of the beam should be suitable for the installation of the roof plate and its accessories recommended to raise the height of about 1 meter.

Step 6: (1) Lift the power side roof plate above the beam by forklift or manual means, and then shift the two sides of the beam to the outside until the two sides of the roof plate pulleys can enter the opening of the two sides of the beam; After the power side roof plate is placed on the beam, align it with the mounting hole of the beam and install it with screws. (2) Install the connecting screws of the baffle plate and the roof plate: tighten and fix the roof plate and the beam B directly with screws; Screw the baffle plate, roof plate and beam A together (Note: the baffle plate should be installed in the direction of the front, the screw on the side of the baffle plate is longer than the screw on the side without the baffle plate, please do not install wrong). (3) Install the non-power side roof plate, install the roof plate to strengthen the connection screws, and then measure whether the column is vertical with a level, correct the vertical column with a horizontal adjustment pad and tighten the anchor screws.

Four column positioning lift installation step seven: (1) The roof plate has been wound wire rope through the column according to the serial number. (2) The wire rope through the beam, through to the top plate of the column with nuts to lock. (3) Effect drawing of steel wire rope worn by the roof plate. (4) Install the safety mechanism connection rod and control handle.

Four column positioning lift installation step eight: (1) Install the hydraulic station and hinged casing. Hinged casing fixing plate, hinged casing through the hinged casing fixing plate, with M8*25 hex socket screw with a cartridge medium installed in the two holes (safety mechanism connection rod and hinged casing connection) (2) hydraulic system installation, note: when the oil pipe and return oil pipe connected to the oil cylinder must pass above the wire rope and the oil cylinder inlet upward tilt, to prevent the wire rope scraping the oil pipe or return oil pipe.

Four column positioning lift installation step nine:

1. Connect the two wires (live wire L and neutral wire N) of the external power cable to the wiring terminals marked L1 and L2 on the AC contactor.

2. The two lines in the motor of the hydraulic station are respectively connected to the terminal marked T1 and T2 on the AC contactor.

3. Connect AC contactor A2 to L2

4. The two lines on the button switch are connected to the wiring terminals labeled A1 and L1 on the AC contactor respectively.

Single-phase (220V) hydraulic station motor wiring 2

one The live wire (L) of the external power supply is connected to the 4 # wire of the push button switch.

2. The 3 # line of the push button switch is connected to the 6# line of the motor.

3. The 5# line of the motor is connected to the neutral line (N) of the external power supply.

Note that forklift trucks are required to assist the installation during the installation process! In addition, the foundation and power supply must meet the technical requirements, and remember to apply grease on the relevant parts of the power movement after loading.